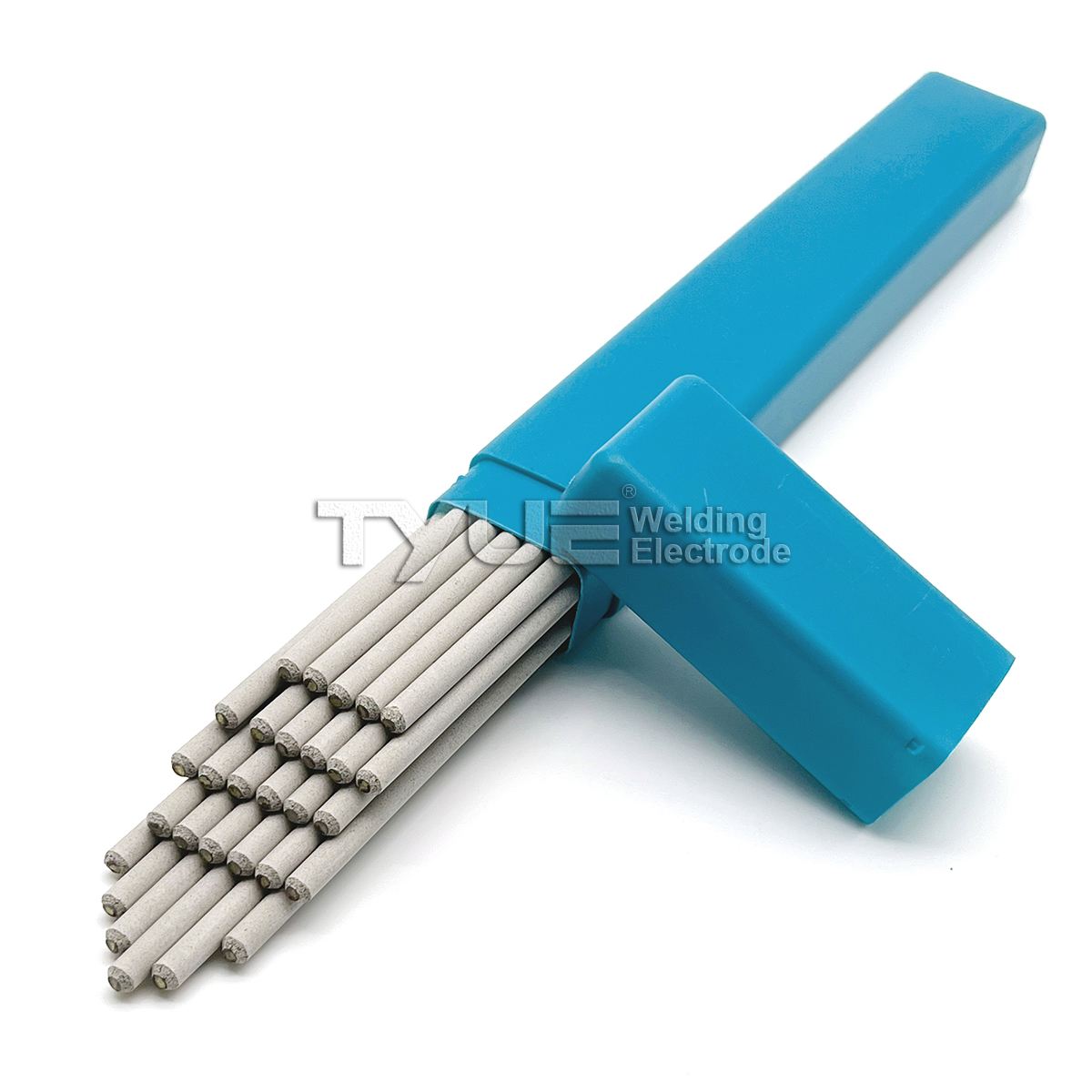

Alloy dị alaIgwe ịgbado ọkụElectrode

J607

GB/T E6015-D1

AWS E9015-D1

Nkọwa: J607 bụ obere alloy dị elu na-arụ ọrụ nke ọma nke nwere mkpuchi sodium dị ala.Jiri DCEP (electrode ziri ezi dị ugbu a), enwere ike ịgbanye ya n'ọnọdụ niile.

Ngwa: Eji maka ịgbado ọkụ ọkara carbon ígwè na ala-alloy elu-ike ígwè Ọdịdị nke kwekọrọ ekwekọ ike, dị ka Q420, wdg.

Ngwakọta kemịkalụ nke igwe weld (%):

| C | Mn | Si | Mo | S | P |

| ≤0.12 | 1.25 ~ 1.75 | ≤0.60 | 0.25 ~ 0,45 | ≤0.035 | ≤0.035 |

Njirimara nke igwe weld metal:

| Nwalee ihe | Ike ọdụdọ Mpa | Mpụta ike Mpa | Ogologo oge % | Uru mmetụta (J) -30 ℃ |

| Ekwenyere | ≥590 | ≥490 | ≥15 | ≥27 |

| nwalere | 620 ~ 680 | ≥500 | 20 ~ 28 | ≥27 |

Ọdịnaya mgbasa hydrogen nke ọla edobere: ≤4.0mL/100g (usoro glycerin)

Nyocha x-ray: akara ule

Akwadoro ugbu a:

| (mm) Dayameta mkpanaka | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 | 5.8 |

| (A) Welding Ugbu a | 60 ~ 80 | 70 ~ 90 | 90 ~ 120 | 140 ~ 180 | 170-210 | 210 ~ 260 |

Mara:

1. The electrode ga-abụọ maka 1 hour na 350 ℃ tupu ịgbado ọkụ ọrụ;

2. Ọ dị mkpa iji kpochaa nchara, ọnụ ọgụgụ mmanụ, mmiri, na adịghị ọcha na akụkụ ịgbado ọkụ tupu ịgbado ọkụ;

3. Jiri obere arc arụ ọrụ mgbe ịgbado ọkụ.Ụzọ ịgbado ọkụ dị warara kwesịrị ekwesị.