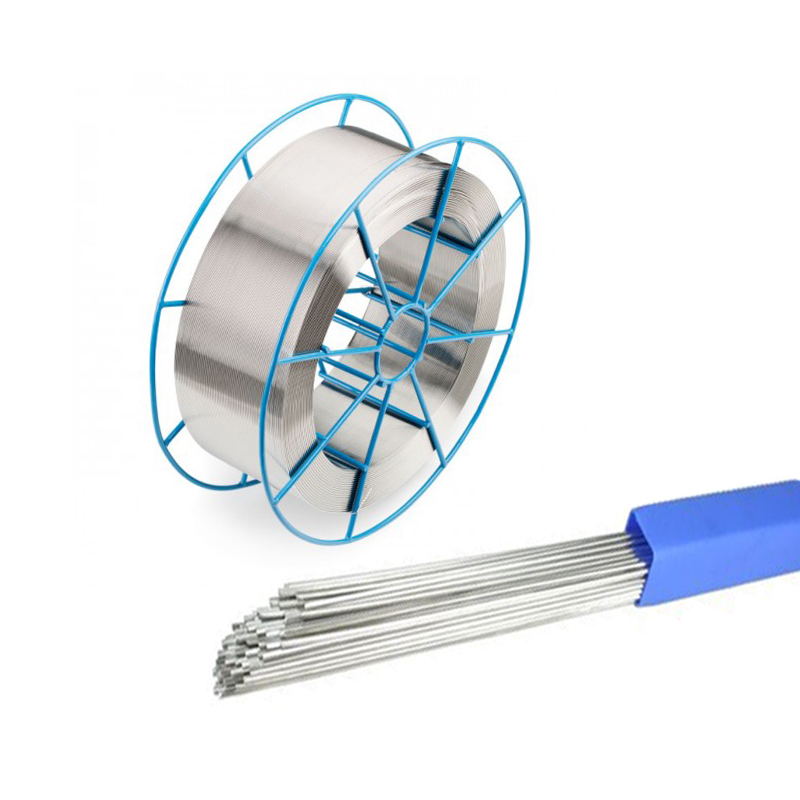

Nkọwapụta ngwaahịa:

AWS: A5.14

Dabara na Asambodo: AWS A5.14 ASME SFA A5.14

Usoro Weld: Usoro ịgbado ọkụ GMAW & ASAW

ERNiCrMo-10 na-eji maka ịgbado ọkụ nickel-chromium-molybdenum isi ihe onwe ha, ígwè na ndị ọzọ nickel base alloys, na maka cladding steels.Enwere ike iji weld duplex, super duplex igwe anaghị agba nchara.

Achọrọ ihe mejupụtara kemịkalụ AWS

| C = 0.015 kacha | Cu = 0.50 max |

| Mn = 1.0 max | Ni = fọdụrụ |

| Fe = 3.0 max | Co = 2.0 max |

| P = 0.04 max | Cr = 14.0 - 18.0 |

| S = 0.03 max | Mo = 14.0 - 18.0 |

| Si = 0.08 max | W = 0.50 kacha |

| Ndị ọzọ = 0.50 max | Ti = 0.70 max |

Biko kpọọ maka ozi ndị ọzọ na nha dị:

Ngwa

ERNiCrMo-7 na-eji maka ịgbado ọkụ nickel-chromium-molybdenum isi ihe onwe ya, ígwè na ndị ọzọ nickel base alloys na maka cladding ígwè na NI-CR-MO weld ihe.

PARAMETER EKPERE:

| Ngwakọta kemịlụ echekwabara % (Ọtụtụ) | ||

| C = 0.01 | kr = 16.5 | Ni = Balance |

| Fe = 2.20 | M = 15.75 | |

| Ngwongwo igwe weld niile etinyegoro % (AW) | ||

| Ike ọdụdọ | 113,00 psi | |

| Ogologo oge | 29% | |

ALA MMETỤTA CHAPY-V-NOCH KWESỊRỊ:

Ọ metụtaghị

| Oke ịgbado ọkụ akwadoro maka MIG na SAW Welding nke Nickel Alloys | ||||

| Usoro | Dayameta nke Waya | Voltaji (V) | Amperage (A) | Gas |

| MIG | .035 inch | 26-29 | 150-190 | 75 % Argon + 25% Helium |

| .045 inch | 28-32 | 180-220 | 75 % Argon + 25% Helium | |

| 1/16 sentimita asatọ | 29-33 | 200-250 | 75 % Argon + 25% Helium | |

| SAW | 3/32 sentimita asatọ | 28-30 | 270-350 | Enwere ike iji Flux dabara adaba. |

| 1/8 sentimita asatọ | 29-32 | 350-450 | Enwere ike iji Flux dabara adaba. | |

| 5/32 sentimita asatọ | 30-33 | 400-550 | Enwere ike iji Flux dabara adaba. | |